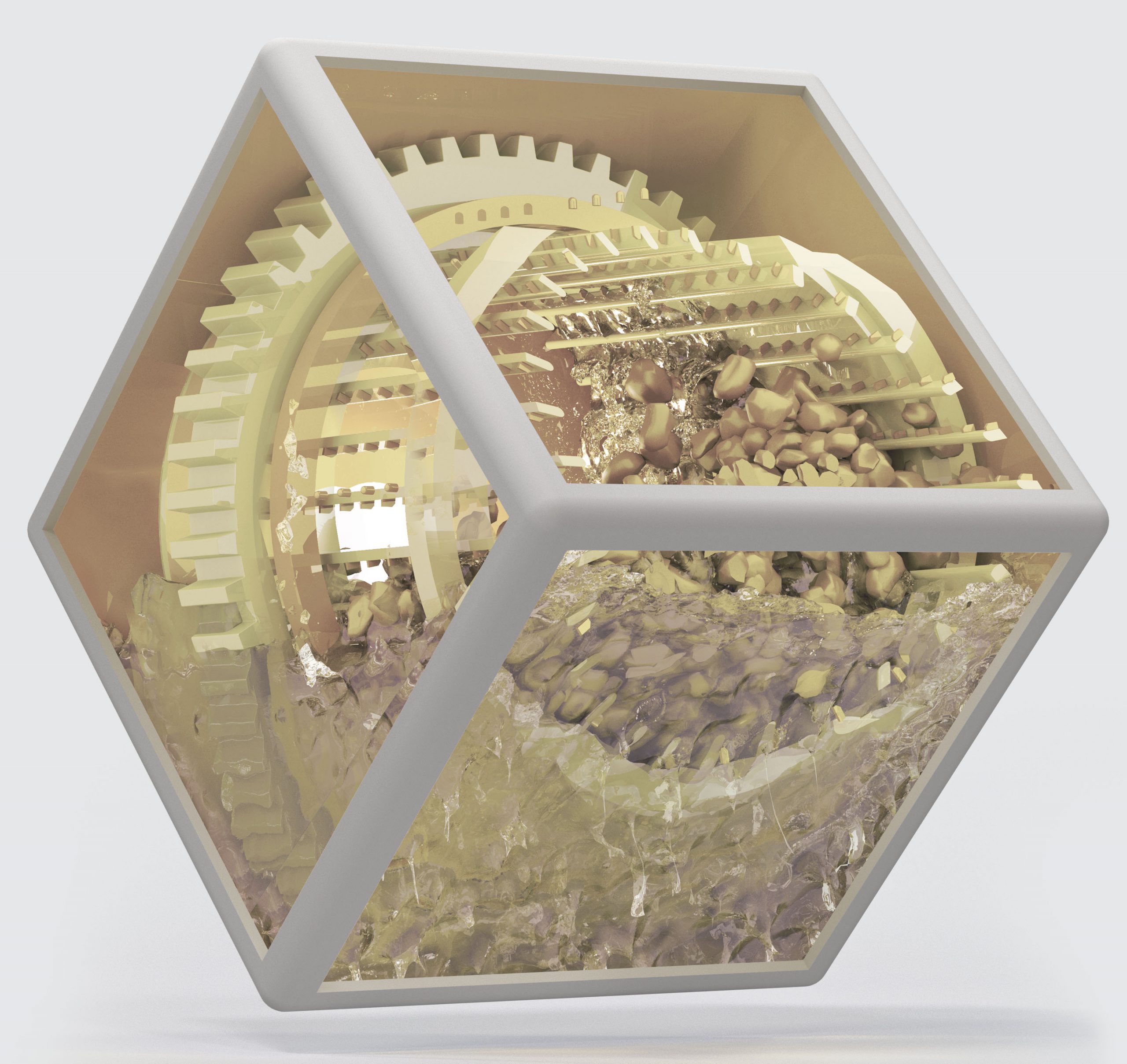

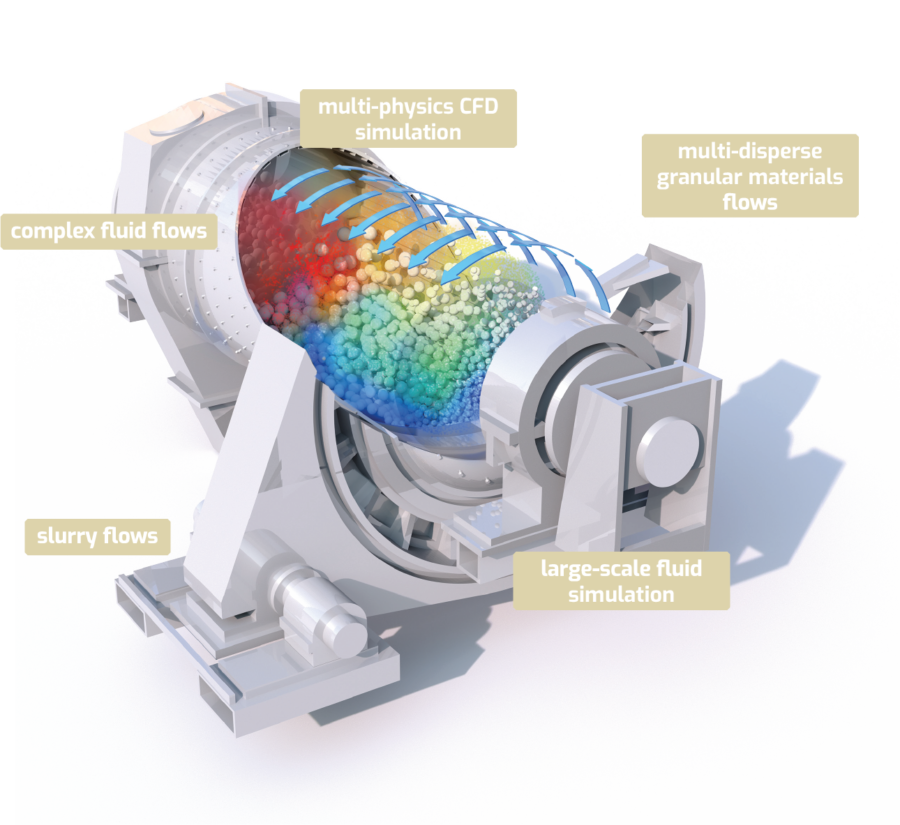

alsim Processing

alsim Processing can model even the most complex problems – dry multi-disperse granular material flows, free surface & non-newtonian fluid flows, agglomeration, coagulation, flotation, bubbly & slurry flows, crack and crush in milling – with highest accuracy. Our solver combines particle-based methods (SPH, DEM) with mesh-based methods (LBM, BEM, FDM), enabling us to simulate demanding multiphysics problems.

We can improve performance of existing facilities and equipment. Moreover, they can be optimized in the design phase, thus saving capital costs, energy and precious materials in tailings. We aim to reduce the impact incurred on the environment owing to the processes involved in the processing industry.