Poorly or non-painted areas creating complexity in your paintshop workflow?

Time and labor is being invested where it does not have to be. If you don’t get rid of poorly or non-painted areas, your workflow cannot be fully optimized. It will have gas bubbles that cannot escape and too much liquid might remain on the object.

Oftentimes experts are left spending precious time preparing processable input geometry suitable for simulations. CFD experts understand that accurate simulation of two-phase flows is impossible for complex geometries. Meanwhile, process experts in production are left waiting. Standard CFD is not suitable for process experts because it is highly complex, has extremely slow calculation times, and requires high computational power.

For example, if a process expert wants to implement a new car body type in an existing production line, it is not possible nor probable because it requires CFD expertise, powerful hardware, and valuable time. Dipping and draining optimization must save time and ensure precision and accuracy.

The ESS Solution

alsim Paint Shop Dip Paint is the exception and the solution. It enables simulation within 24 hours and all on an affordable desktop PC or laptop. It is precise, user friendly, and cost and time efficient.

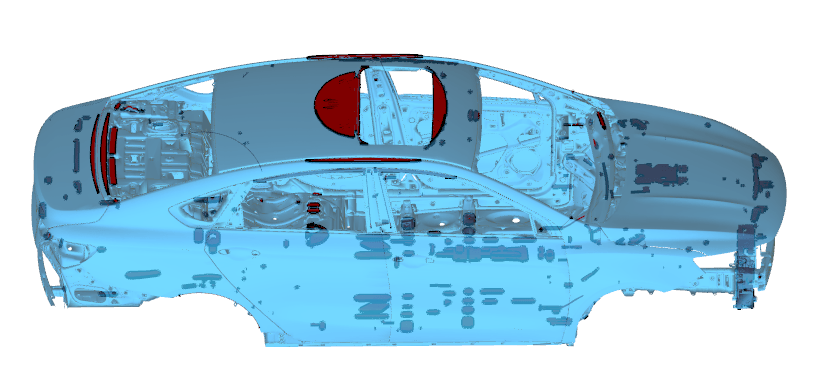

Within alsim Paint Shop, the Dip Paint module is a two-phase simulation software. This tool aids in avoiding non or insufficiently painted areas caused by gas bubbles and it secures full control of air behaviour while immerging and dipping through a tank.

alsim Paint Shop Dip Paint has absolute full control of air and fluid drainage on full car bodies. Original CFD methods require CFD experts, have slow calculation times, and require too much computational power. These methods use normal 3D mesh but are faced with problems because the number of elements explodes in a two-phase simulation.

ESS software avoids these problems although the computation is two-phase. It doesn’t require the best surface mesh, yet it can automatically capture boundary representation of the input geometry with exact precision. No other software is capable of this. We use a proprietary method and the decomposition of space outside the geometry is done internally.

Furthermore, alsim Paint Shop Dip Paint is not only way faster than other methods, it predicts drainage time even for the smallest holes, with utmost precision.

The alsim Paint Shop suite delivers a scalable suite of products that allow all users, regardless of their simulation expertise or domain focus, to collaborate and seamlessly analyze and optimize the design and applications of your engineering processes.