The automotive industry is at the cusp of a revolution, with electric vehicles (EVs) taking centre stage. As the EV market expands, the quest for top quality paint finishes intensifies.

But how do we navigate the intricate process of painting EVs, especially the rocker panels? ESS’s alsim Paint Shop Software suite might just have all the answers.

The Evolution of ESS in the Automotive Painting Landscape

Foundation & Growth:Established in 2015, ESS has since built partnerships with over 60 global car manufacturers and suppliers. Since inception, our results have been improved, validated for its accuracy, and approved and implemented by our customers in their daily paint shop activities.

The alsim Paint Shop Platform: This innovative platform takes care of diverse paint shop applications, from sealing to e-coating and oven curing. Its introduction has been crucial in refining both new and existing paint shops, and design of parts and BIWs, ensuring uniform and top-tier finishes.

The Unique Challenge of Rocker Panels in EVs

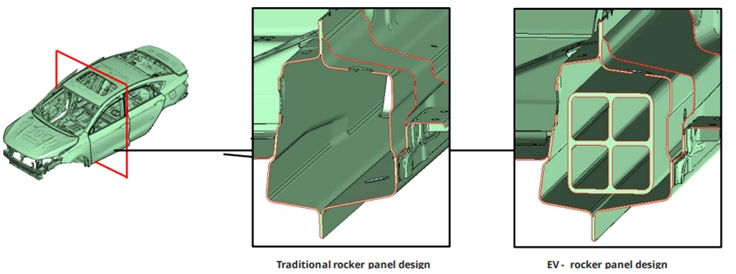

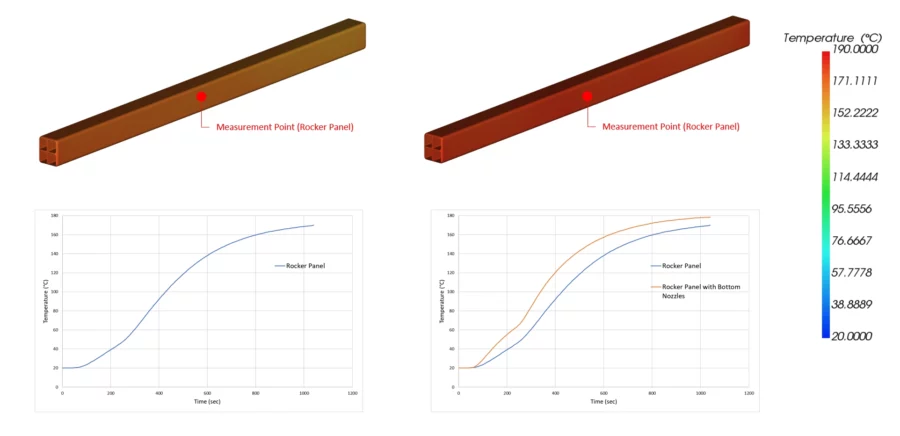

Painting Complexities: EVs have undergone significant design alterations compared to their traditional counterparts. The introduction of added materials in the rocker panels, essential for crash safety due to the weight of EV battery packs, complicates the painting process. This design can trap air bubbles, and hinder paint particle deposition during the E-coating phase. Similarly, greater liquid carry over can impede the Oven process. Additionally, the presence of different materials in the rocker panel design also affects the painting process due to the difference in the material properties. The significant difference in the design of EVs, with respect to the battery case, grail and casting rear floor have all added to the complexity of painting EVs.

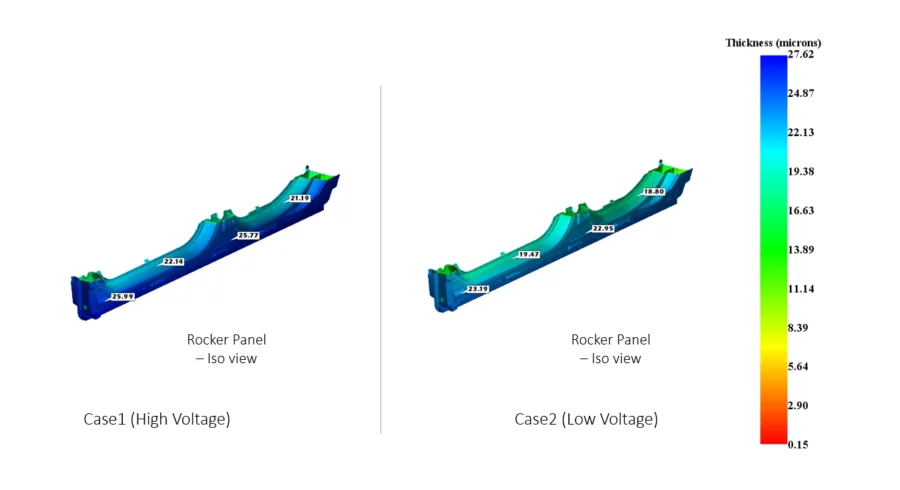

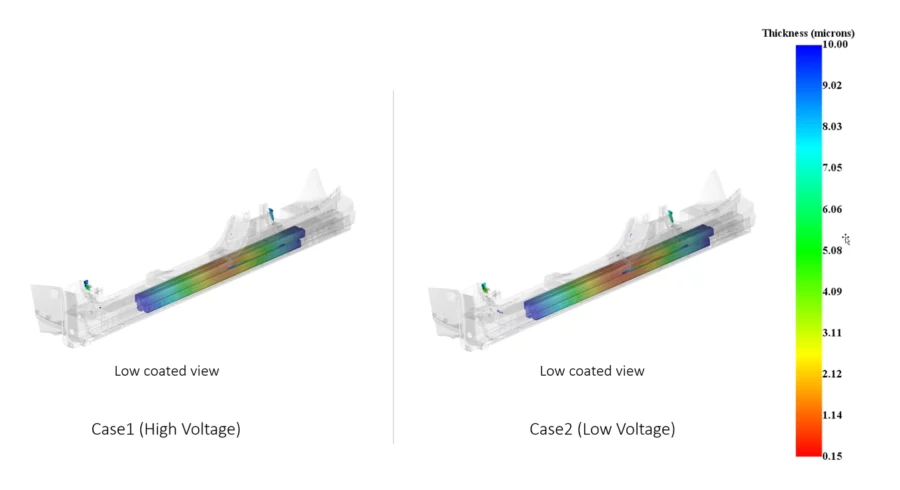

Changes in process parameters: To accommodate the complexities involved in painting EVs, it is crucial to adjust the process parameters and find the right method for attaining uniform paint thickness. For example, the complexity of the EV design needs a heightened electric potential during e-coating, posing challenges in achieving uniform corrosion protection otherwise.

These added materials demand a greater amount of energy to heat up the car body during the oven process. Attaining this is tricky, as it can cause damage to external parts from over-heating. Also, the smaller gaps at the rocker panel, reduces the possibility to attain needed electric potential for painting during E-coating. These added complexities make rocker panel painting in EVs, a much challenging ordeal.

Harnessing the Power of ESS’s alsim Paint Shop

Digital Twin Creation

The alsim Paint Shop suite offers a digital mirror of the painting process, enabling paint flow predictions and potential issue identification, for all regions of an EV.

Data Precision

Accurate data, ranging from paint specifics to the vehicle’s trajectory through the paint shop, is paramount for these simulations. The software suite has been built by experts with several decades of industrial experience having closely worked with automotive giants.

Module Integration

The suite’s modules, such as “alsim Paint Shop Dip Paint” and “alsim Paint Shop E-coating”, play a crucial role in addressing each problem area associated with each process in automotive paint shop.

Example of the Solution’s Effectiveness

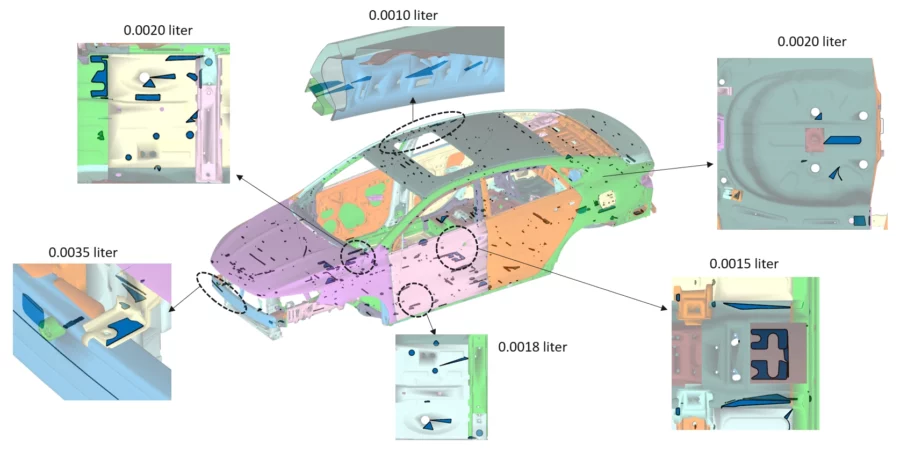

Engine Hood Angle Optimization: Challenge associated with determining the optimal angle for opening engine hoods is an example of – how timely prediction and optimization are crucial to the process. A mere 1-degree alteration of the hood can drastically influence air bubble and puddle formation.

Through the alsim Paint Shop Dip Paint, it was identified that a minor shift from a 7-degree to a 12-degree opening angle of a car model had a drastic impact on its drainage and was a solution to minimize paint puddles by at least half-a-litre!

The Advantage of Adopting ESS’s alsim Paint Shop Software Suite

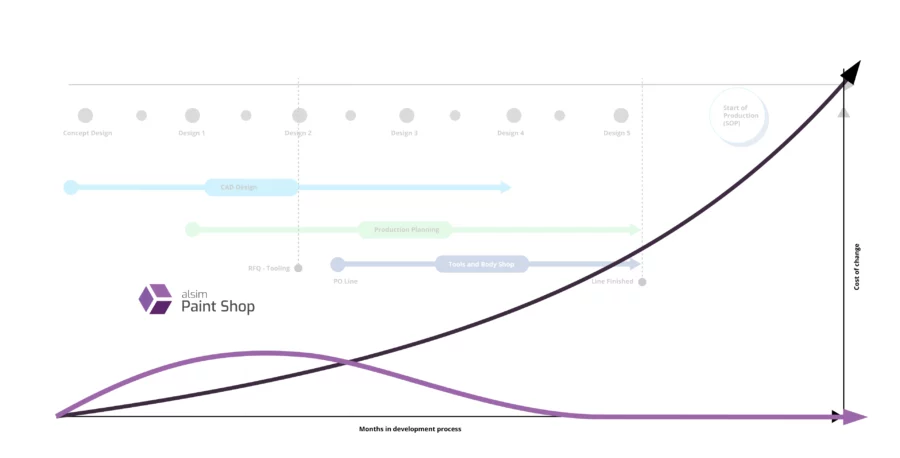

Tangible Benefits: Automotive paint shop professionals stand to gain immensely from the alsim Paint Shop suite. It promises not only a flawless finish but also substantial cost and material savings, even more importantly, the development time. Just the material costs saved from a single BIW, if calculated for the whole batch of vehicles produced in a year, accumulates to a substantial cost in the range of hundreds of dollars at least!

Operational Efficiency: The suite’s ability to optimize the painting process translates to reduced paint wastage, diminished rework, and extended paint job longevity. This is not just about fixing the problem areas, but also about identifying potential wastage and saving them. And what’s more? The software has been designed for non-CFD experts – which means, there is little to no training needed for the users to get started. And the automated reporting feature makes it extremely easy to learn from the results of your simulation runs.

Contact us today!

For those steering the helm in the automotive painting domain, embracing the alsim Paint Shop software suite is not just a choice—it’s a strategic move. As we accelerate into the EV era, it’s time to harness this cutting-edge tool to navigate the challenges of painting EVs and chart a course for a brighter future. Contact us today for a free consultation!