E-car or Combustion engine: The big difference in painting

Our CEO – Dr. Martin Schifko, was recently interviewed by an Upper Austrian Newspaper (Oberösterreichische Nachrichten) about this topic, where they discussed about the challenges faced by the automakers currently, and how ESS is working towards solving this issue. Read the original article in German here. The translated version of the article can be found below.

“The painting process for cars has a tradition”, says Martin Schifko from Steyr. “Major issue is because every change costs a lot of money and also time. That’s why nothing has changed in the last 30 or 40 years. “

Complicated processes

The fact is that painting cars is a fine art. First, car bodies are cleaned, degreased, phosphatized and dried again and again. Depending on the method, this is followed, for example, by cathodic dipping, the fine seam sealing and finally the multi-stage paint application. Not only does the appearance count, but above all perfect corrosion protection.

Tricky: Paint drying

The biggest challenge is drying the paint. A drying line is usually 120 meters long and takes 90 minutes to pass through. In it the car bodies are dried for around 15 minutes to 150 to 180 degrees and then slowly cooled down again. “If this cooling process happens too quickly, adhesive joints between steel and aluminum can break,” says Schifko. If it’s too hot, the the chemical chain in the adhesive does not take place. This means that the adhesive cannot withstand the stresses.

Air pockets in the paint are also a common and expensive phenomenon in the paint. In premium cars, a total of 100 square meters must be painted – including the cavities in the underbody. For compact models it’s still 60 to 80 square meters. That’s why the the layers are applied extremely thinly. Because the thicker a paint, the heavier the car. That adds kilograms of extra weight that quickly adds up to the overall weight.

Currently, the painting processes for internal combustion cars have to be converted to electric cars. “A very big challenge,” says Martin Schifko. The heavy batteries mean that additional structures have to be placed in the sill. And just these struts with their cavities also have to be protected from corrosion. “These more extensive structures absorb more energy during heating up and often heat up differently,” says the Steyr native. Then the paint does not adhere as desired. Converting a coating line can easily cost two- to three-figure sums.

Sophisticated simulation

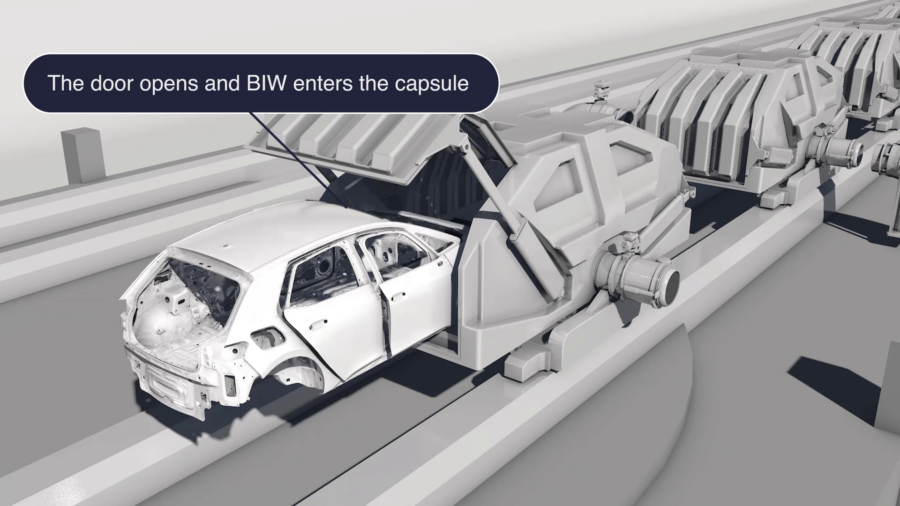

To save money, Martin Schifko and his company Engineering Software Steyr (ESS) develops simulations for paint shops. Almost all well-known car manufacturers are now among his customers. Among them are also some Chinese car manufacturers. In order to get a grip on the different heating of the car bodies, the Steyr-based company has also developed capsules into which a car frame fits exactly. Inside these the constructions more precisely with hot air. And each capsule can be model. The first interested parties have already knocked on the Steyr’s door.

ESS: THE HISTORY

Since 2003, the Magna Engineering Center has been developing software on behalf of Audi to simulate painting in a dip tank, with the main aim of preventing air pockets. In 2015, Martin Schifko and his company Engineering Software Steyr (ESS) bought the simulation software and has since been expanding the subject area. Not only air inclusions, but also cathodic dip painting, waxing, fine seam sealing, etc. can now be represented on the computer. In Steyr, the entrepreneur now employs 50 people, and there are ESS sites in Poland, India and Turkey. 50 car manufacturers – including Tesla and Daimler – are among the customer base.