NME magazine features ESS

ESS seeks to enter the South American Mining Industry

European company, Engineering Software Steyr GmbH (ESS) is establishing their entry into the South American mining industry in the upcoming months. They provide software solutions that help in improving the overall efficiency of industrial processes and production lines.

The development of such software solutions (based on CFD methods) has been the prime focus of ESS since the company foundation by Dr. Martin Schifko. With an impressive track record not restricted to the European market, ESS is one of the key players in the world of CFD simulations in the automotive industry, with endorsements from customers such as Audi, BMW, Daimler, Jaguar Land Rover, Volvo. ESS has won the Pegasus award in Gold for “Most promising company in Austria” for 2019, in addition to obtaining the “Start-up of the Year” award for US Market. ESS has also received the prestigious EU funding as a part of the biggest EU Research and Innovation programme – “Horizon 2020”.

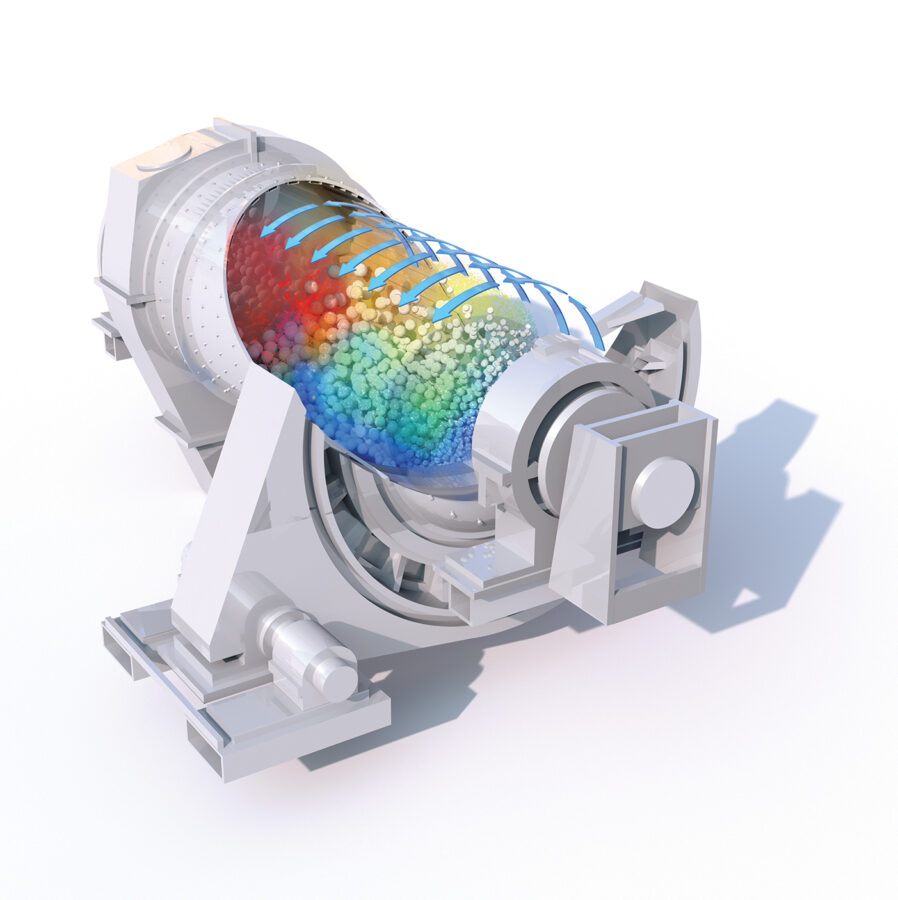

alsim SENSE technology is the latest and third suite of software solutions offered by ESS, since 2015. The profits of employing alsim SENSE in industries that rely on heavy machineries and long production cycles is immense. Mineral processing represents such an industry characterized by sky-high expenditure – both capital and operational. Everything related to this field - equipment, process, and maintenance – amounts to significant investments. Using alsim SENSE helps in identifying potential flaws upfront, and to have enough bandwidth to make corrections by tremendously reducing the expenses. In addition to making these processes environmentally sustainable and energy-efficient, it would eliminate a large amount of resource and time wastage. When applying our approach and optimizing the design of equipment, this would essentially mean an improved efficiency of 50-100% when it comes to energy consumption and the throughput of the device. This would alleviate any loss incurred due to the long production cycles of the device.

The vast experience of the CMO, Dr. Alireza Eslamian, in the field of mineral processing, enabled ESS to gain a thorough expertise in the production of different mineral processing plants and equipment such as – ball mills, floatation cells, rotary kilns, graphite furnaces, thickeners, gigantic power transmission systems, to name but a few. Dr. Eslamian is a Ph.D. graduate in Mechanical Engineering from the SRBIAU in Tehran, Iran. Besides, for over a decade he was the director of two engineering companies in his home country, specialized in designing and manufacturing of the mineral processing facilities and devices. Thus, ESS’s scientific credentials are strongly backed up by solid practical experience in the mining industry.

Considering South America to be a hotbed for the mining industry, with Chile being in the forefront, ESS has recently collaborated with SWG Consult Company to ensure the outreach of their mineral processing software solution to the Chilean market. Walter Stalder, who is based out of Santiago, Chile, would thus be the main point of contact for ESS within Chile. Being a valued member of the productivity circle of ASIMET and with over 20 years of experience in the metal-mechanical industry, he is believed to be the perfect individual to fulfill the objectives foreseen by ESS for the mining industry.

In view of the recent pandemic and the current global economic situation, ESS believes that an innovative approach such as this is crucial for a speedy recovery of the mining industry. Having prepared to enter the Chilean market, the company is eager to delve and engage with potential customers.

Check out the nme magazine in spanish: https://www.nuevamineria.com/revista/agosto-2020-no-138/