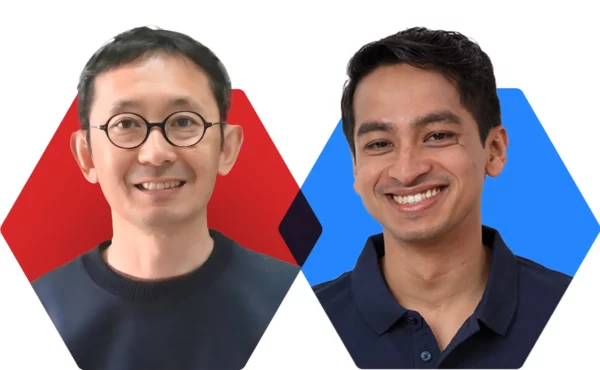

Shaping the Future of Automotive Paint: Insights from Muraleekrishnan Menon and Shuichiro Nakajima

Last month, teams from ESS and ABB Robotics came together in Steyr for a focused three-day workshop. It was a mix of strategy, deep technical discussion, and face-to-face collaboration, all aimed at aligning the two companies on shared development goals. We spoke with Muraleekrishnan Menon, COO at ESS, and Shuichiro Nakajima, Global Head of Paint and Sealing at ABB Robotics, to hear their personal perspectives on the experience and the future of automotive manufacturing.

Shuichiro Nakajima: Innovation Through Global Collaboration

“I’m responsible for the paint and sealing business globally at ABB Robotics,” Nakajima said. With over 27 years at the company, he has seen immense change. “A lot has changed, but I’m proud of our innovations like PixelPaint and other high-tech solutions that have enhanced productivity, reduced waste, and paved the way for cutting-edge digitalization. Collaborating with ESS is an important step forward in that journey.”

Discussing the differences between Europe and Japan in manufacturing, Nakajima reflected, “For me, Europe is often a birthplace of innovation. Working with European customers gives us the opportunity to develop and test advanced technologies before introducing them globally.”

On his white paper, ‘The Future of Paint Shop 2030’, he shared, “We’re facing a knowledge gap as experienced individuals retire. One key objective of the white paper is to address this problem with automation and digitalization. That’s one reason why our partnership with ESS is so important.”

“There are two major factors driving our focus on 2030,” Nakajima explained. “Growing pressure from the UN’s Sustainable Development Goals (SDGs), and the loss of technical knowledge due to aging workforces. By 2030, we must address these with automation, digital tools, and collaborative innovation.”

Looking at regulations, Nakajima said, “We’re always under pressure to boost both sustainability and quality. Paint shops are among the most energy-intensive areas in car manufacturing, so finding ways to reduce emissions and improve efficiency is critical.”

When asked about new technologies leading to the future, Nakajima stated clearly, “Digitalization is the game-changer. The painting process still lags behind in this area. But simulations, especially those combining robotics and process behavior, will play a key role in unlocking productivity.”

He continued, “Simulations let us visualize what experienced workers know intuitively. When we can see a problem, we can solve it. It’s essential for understanding and optimizing painting and sealing processes.”

Discussing RobotStudio, Nakajima added, “RobotStudio is a masterpiece of robot simulation. It already allows customers to simulate robot movement in detail. But when we integrate it with ESS software, we can simulate both movement and the process. That opens a whole new chapter for engineers, operators, and maintenance teams.”

Reflecting on the week, Nakajima said, “This time, I brought not just R&D managers, but key operational people. Over three days, I saw real knowledge exchange between people with different values and expertise. That’s what I enjoyed most, seeing new ideas forming right in front of my eyes.”

The personal reflections of Muraleekrishnan Menon and Shuichiro Nakajima highlight a shared commitment to collaboration, innovation, and sustainability. As ABB Robotics and ESS move forward with their joint roadmap, it is clear that the combination of technical excellence and deep mutual respect will drive the future of automotive manufacturing.

Muralee Menon: Building Trust Through Collaboration

“The idea was to define our joint R&D roadmap to bring together the strengths of both ESS and ABB and figure out how we can build products that make real sense for the market,” Menon shared. “We also wanted to get people in the same room, talk through capabilities, and build better personal connections. Establishing that working relationship really matters for long-term collaboration.”

Menon emphasized that while relationship-building was important, the focus was mainly technical. “We’d already had several virtual meetings, so this wasn’t our first contact. But being in the same room speeds things up as the conversations are deeper, the ideas flow faster.”

“We focused on two things,” Menon continued. “One was predictive maintenance using a digital paint suite, basically building a digital twin that helps detect issues early in production. The other big topic was about how we combine our strengths to create value for different customer persona.”

Reflecting on how the collaboration evolved, Menon said, “You walk in with a plan, but when the right people start talking, new ideas come out. It was three days of solid discussions, very focused. I think by the end of it, both teams walked away with a stronger level of trust and understanding. That’s hard to get over video calls.”

Looking ahead, Muralee explained, “Our goal for this year is to show a working product at the User Conference in October. That’s what we’re aiming for. And now we have a timeline: we know what’s coming to the market, when, and how we’ll build on it in future development cycles.”

On a personal note, Menon added, “I really enjoy these kinds of intense, in-person workshops where the agenda is clear, and everyone’s focused on solving problems. Professionally, the discussions were on point: all about how to bring better products to market. Personally, I really appreciated the diversity of the group, we had people from Sweden, Germany, Japan, China, India, Russia, and Austria. That mix brings different ways of thinking, and I find that incredibly valuable. It was a great experience overall.”