New project to reduce global energy consumption by 1 nuclear power plant

The transportation section accounts for 25% of the global energy consumption making it one of the most challenging sectors for combating climate change and fulfilling the environmental goals proposed. Around 80 million car bodies are produced around the world every year, which results in an enormous power consumption of about 48 billion kWh.

Of the enormous 41.8MJ/kg consumption per vehicle produced, industrial oven is the second highest consumer of energy. A process that is vital to the durability and longevity of a vehicle, the oven (1MW) process requires an average of 150 kWh per vehicle and produces greenhouse gas emissions of 0.2 – 0.4 tCO2e per tonne of body-in-white (BIW)!

It is estimated that the regulations for limiting CO2 emissions in automotive industry could create a penalty of up to 30 billion EUR, equivalent to half of the combined net profits by car manufacturers (as per 2018 figures). But thanks to the latest innovation from ESS, there is an easier solution. The new concept, namely the selective induction method, promises to reduce energy consumption by approx. 9,936.0 GWh annually, equal to 1,540,080 metric tons of CO2. Simply put, that’s more than the annual output of 1 nuclear power plant!

Selective Induction Method

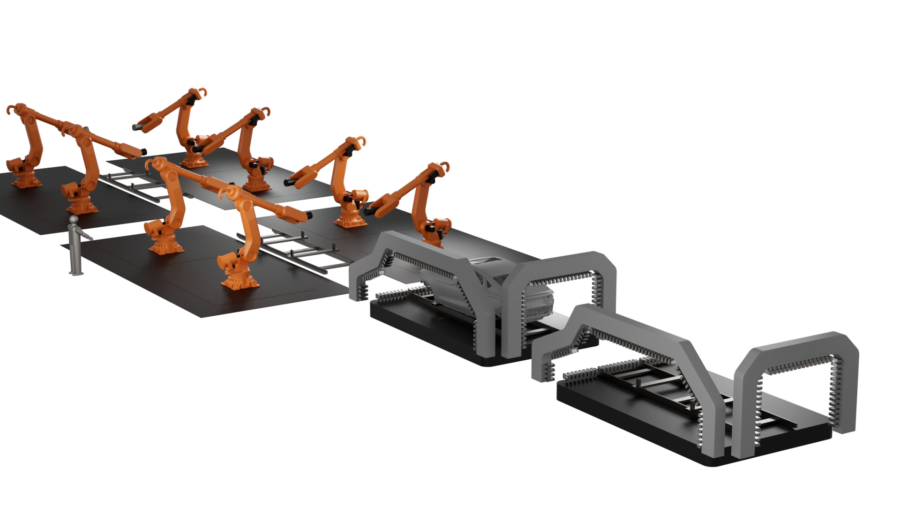

The concept developed in InduHEAT project, backed by Austrian Research Promotion Agency (FFG), will shape a new process for optimization with induction for curing the anti-corrosion coating on vehicles. Engineered by a consortium, it will be simulated in the form of a digital twin and a final manufactured product.

By developing this innovative energy technology, we expect to save the customer 8.69 EURO per car body, which means a cost reduction for the entire market in the amount of approx. 700 million EURO per year. This is in addition to the ecological benefits of drastically reduced energy consumption and CO2 emissions.

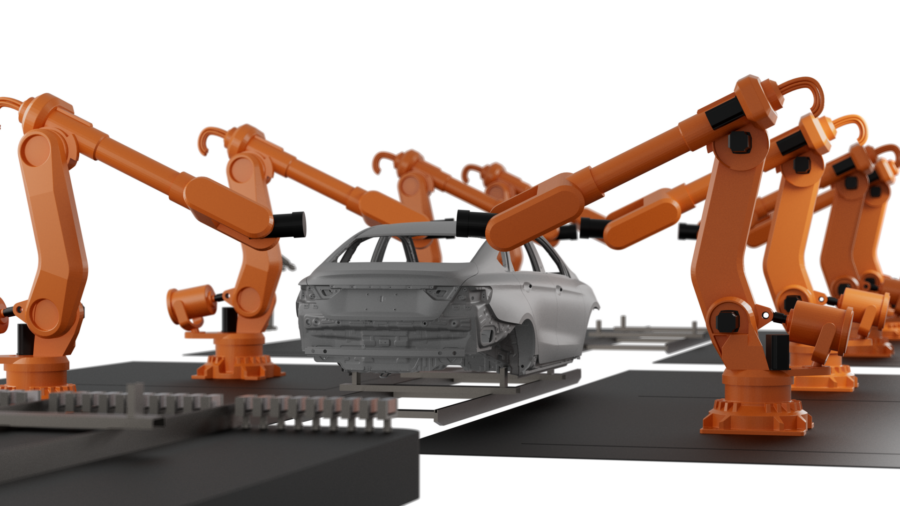

The innovative induction method uses special nanoparticles added to the painting fluid to absorb induction energy through interaction with electro-magnetic field, which is then absorbed by a thin layer of coating on the car body. The enhancement allows the adjustment of time scale for the hardening of the coating and improves the surface sensitivity to absorb required curing energy.

Presence of a digital twin adds immense flexibility to simulate changes to the manufacturing process because of our innovations. The costs are further heavily reduced as it removes the burden on physical prototypes.

About the InduHEAT project

Before the study, initial tests were carried out at ESS and a patent for the concept was applied. The patent and the know-how gathered during this will be utilized for the project completion. Consisting of a multi-disciplinary team, ESS leads the project on the design, simulation and optimization front, and Institute of Thermal Engineering – Graz University of Technology, led by Prof. Hochenauer, provides the environment for real-world lab testing of the final product.

The Institute of Mathematics & Computer Science – University of Southern Denmark, led by Prof. Ralf Zimmerman, will aid the project by providing the mathematical methods to apply multidisciplinary optimisation to deduct a homogenous inductive field for complex shapes like car-bodies to avoid over- and under- heating. The settings for such real-world applications can only be derived by a proper simulation software upfront. The algorithm needed to conduct computations in the simulation software and to ensure feasibility of our innovation is to be developed in the project.

Apart from the development of a digital twin, Prof. Nico Gauger of Technical University of Kaiserslautern Germany will contribute towards manufacturing the oven as a third-party contributor. With all in place, and well in progress, the project is expected to revolutionise the markets with its completion by Feb 2024.