Definition of the problem

Gearboxes are manifold in nature and traditional simulation methods can no longer keep up with their ever in-creasing radical complexities. Optimization is therefore more and more important and necessary in order to save time and money on expensive prototypes.

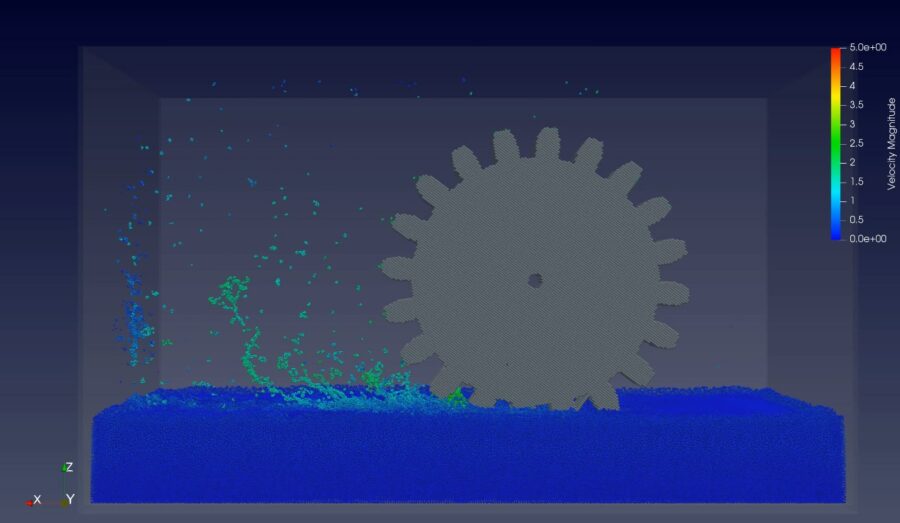

The gearbox simulation demonstrates the simulation of a rotating gear (or gearset) in any kind of fluid in order to understand free surface dynamics in the in the gearbox.

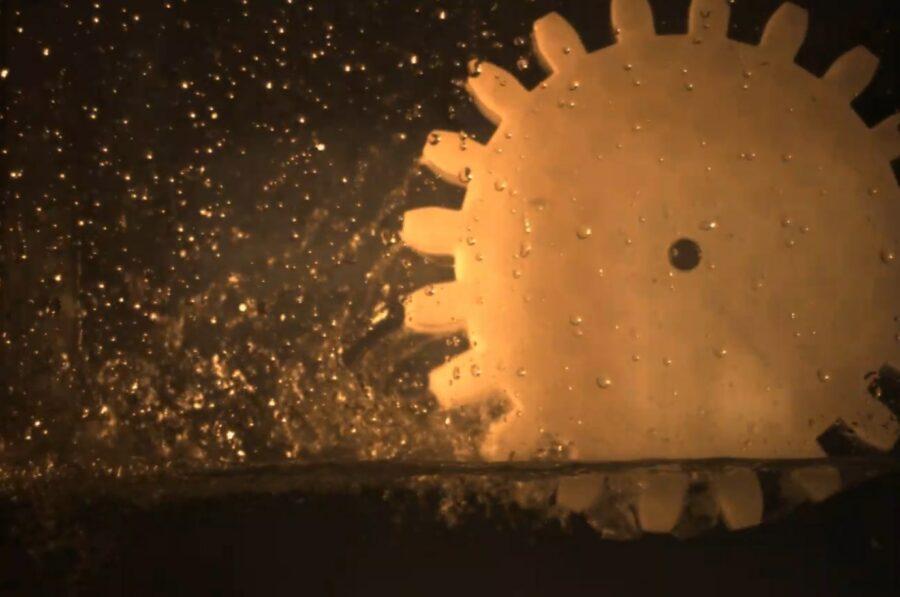

The simulation involves free surface model, turbulence, multiphase, and surface tension. The rotation of gear encounters churning loss when it interacts with the fluid and it increases when the viscosity heightens.

Therefore, it is important to observe how the efficiency of the gearbox varies with respect to the type of fluid and opera-tional speed. The goal for the Gearbox simulation is to assure both longevity and performance.

It needs adequate lubrication and at the same time, churning loss should be minimal. There are several suppliers in this segment today but up until now, accurate results usually required much time and lots of manual work, which accounted for high costs, while fast results always lacked accuracy.

ESS has the only solution that is both accurate and fast and therefore cost-efficient. What more could one want?

alsim Mobility Gearbox

The alsim Mobility Gearbox Simulation allows the user to setup a simulation case for gear rotation to observe the interaction with free surface. The module uses multiphase calculations, which are essential as air is sucked into the liquid.

It also considers the temperature of liquid and materials as this influences the viscosity of the oil as well as the longevity of the gear unit.

With alsim Mobility Gearbox, fluid properties can be specified and the gears can be set to time-based rotation, which includes the dynamic variation of rotation speed. Autonomous mesh preparation is provided in the same easy way as for all other ESS applications.

The GUI pre-defines and facilitates control boundary conditions and gear rotation speed. The total simulation time can be set and different filling levels can be successfully and accurately simulated within a few hours. Additionally, churning loss can be determined and improved.

alsim Mobility Gearbox is the application that supports and meets the needs of process and design teams as they drive tomorrow’s product innovations.

alsim Sense Gearbox Simulation

Experimental Gearbox Validation